Mar 24, 2022 · Blunted bevel heel and sharp point. Use only once. Consistent lubrication on the needle surface. Technique: Puncture within the target circle on the stopper. Insert at proper angle. Insert needle slowly. Do not rotate during insertion. Note, multiple punctures increase the chance of coring and fragmentation.

224 difficult to access. One approach for disinfecting the vial septum in this type 225 of vial shield is to use a right-angle forceps to hold a sterile 70% IPA wipe 226 and direct it down onto the vial septum. It is also acknowledged that such 227 vial shields will disrupt first air contacting the vial septum during certain 228 handling

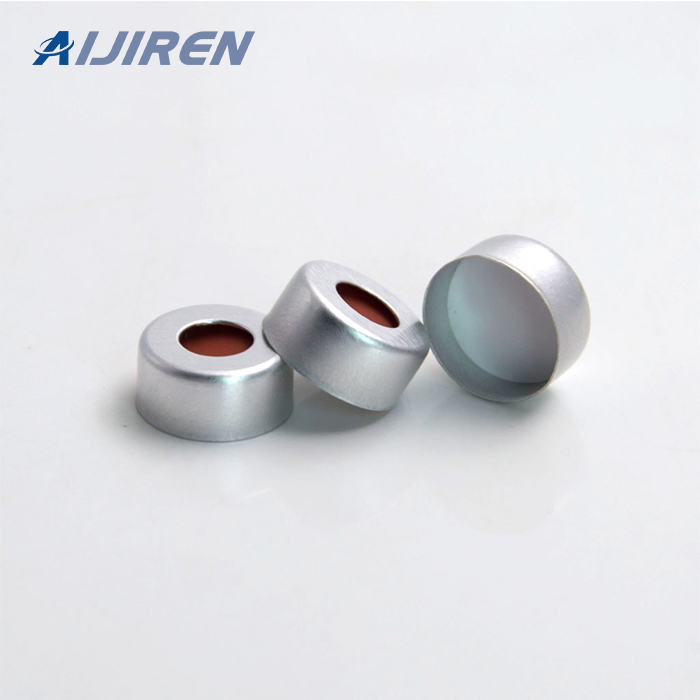

Polypropylene 12 x 32 mm Screw Neck Vial, with Cap and Preslit PTFE/Silicone Septum, 700 µL Volume, 100/pk. Ensure all your solvents, solutions, and samples are stored safely within a chemically inert environment with the Polypropylene Screw Neck Vial, with Cap and Preslit PTFE/Silicone Septum. All Aijiren Technology vials are produced and go through

Pharmaceutical rubber closures are an important component to maintain the integrity of the drug product. They act as a barrier against moisture, air, oxygen etc. Stoppers are partially placed on vials prior to transferring to the lyophilizer and the vials are completely stoppered at the end of the cycle at a pre-determined vacuum level.

Find septa-vials and related products for scientific research at MilliporeSigma thread for 13-425, PTFE/red rubber septum, for use with 4 mL vials with 13-425 ...

The quality and selection of consumables used in chromatographic analyzes directly affect parameters such as analysis accuracy and reproducibility. Thus, sample vials used in chromatography are generally produced from first class hydrolytic glass or high purity Polypropylene (PP) materials. Choosing the right septum is very important to prevent contamination and to prevent damage to device

Jan 2, 2006 · Figure 3 - Typical mass chromatogram of volatile residue in hexane caused by PTFE/silicone septa: a) hexane extract of a piece of septum; b) vial septum was punctured once by a syringe to sample 1 μL hexane for GC analysis; c) hexane in the last vial was reanalyzed after 3 days; and d) analyzed immediately after 100 μL hexane was added from one vial to another (the septum was punctured 10

Mar 16, 2021 · Ready-to-Use Sterile Vials. SCHOTT adaptiQ ® vials are high-quality, sterile and ready-to-use (RTU) for the pharmaceutical and, in particular, the biotech industries, and can reduce time-to-market and increase flexibility. The adaptiQ ® RTU vials portfolio is part of SCHOTT iQ ® – the global RTU standard.

Open-top vial: Open-top vials feature an inert polypropylene screw cap. The cap has a hole in the center and a silicone or polytetrafluoroethylene layer, called the septum, underneath. The septum forms an airtight seal. With the open-top cap, an autosampler needle can easily pierce the septum and access the sample.

Time Vial equilibration: 120 minutes for PS powder, 30 minutes for standard, inject time, 0.5 minute Vial 20-mL HS vial; vial shaking setting, 9; vial pressurize from 15 psi to 10 psi at 20 psi/min by a filling flow 50 mL/min Extraction mode Multiple; 12 times per vial In the MHE mode, the headspace analytes are extracted stepwise.

Dec 7, 2020 · One of the challenges a drug manufacturer faces is controlling the drug product at the point-of-use in a hospital or clinical environment. Often the method of vial access is variable, leading to an increased risk of harmful patient outcomes such as stopper cores or fragments entering into the drug product, which can contribute to cardiovascular events. There are a number of

Type 1 borosilicate glass. Clear glass vials with 20mm crimp seal finish are designed to fit most headspace autosamplers. Flat bottom vials maximize heating efficiency when used with bottom. Round bottom vials are more easily handled by robotic arms that lift the vial from the tray. Round bottom vials distribute the internal pressure created at

This method of leak test of the colored vial in pharmaceutical manufacturing usually used for pharmaceutical blister packaging. This simple visual test is the oldest of the three testing methods. It uses methylene blue dye or another colored chemical liquid to determine whether there is a leak or not.

Jan 2, 2008 · Mobile phase flows inside needle during analysis, washing process cleans outside part of needle. Don't forget to left washing vial vithout septum. If washing vial is closed, cleaning is not effective. When carry-over persists, disconnect needle and needle seal and sonicate in methanol (or water based phases if your mobile phase contains buffer).

And the pharmaceutical companies would take time to vet the new vials through robust quality systems. But the investment and patience would be worth it to potentially create a new multibillion-dollar-a-year growth engine for the company. By mid-2020, several pharmaceutical companies were evaluating Valor Glass.